After taking over industry, robots are now conquering the medical sciences.

The advantages are obvious: absence of fatigue, maximum precision and speed, optimum ergonomics. Experts see their use as the next evolution in the treatment of patients. Already today, robot systems are used in a number of surgical applications, such as in orthopaedics, in neurology or in cardiothoracic and ENT surgery. In addition to established manufacturers, innovative start-ups are entering the market.

Medical technology relies on FAULHABER not only in robot-supported procedures. For example, drive systems are used in implantable heart pumps, surgical hand tools, in ophthalmology, in cosmetics and in medical imaging and image processing.

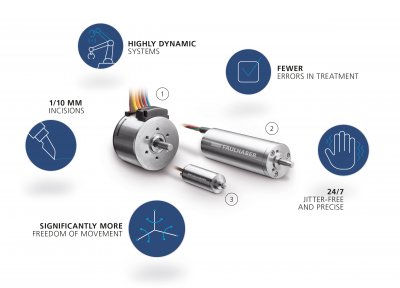

An air of quiet concentration prevails in the operating room. The team prepares the patient for the operation. But the first incision is performed not but a doctor, but by a robot. The surgeon sits focused in front of his surgical console and uses the joysticks to control the robot arms that are used for the procedure performed at the operating room table. Even after a 24-hour shift, the robot cuts absolutely precisely and smoothly. The camera, which is important above all for minimally invasive operations, provides optimally prepared images absolutely free of vibrations. On the 3D monitor, the doctor can see exactly what is happening in the patient’s abdomen. Instead of the conventional 2D view, which is often very limited, he can see every detail on the 3D monitor. In addition, the slim, high-tech arms offer considerably more freedom of movement when cutting, repairing or suturing compared to standard procedures. Because the body of the patient is precisely measured prior to every operation, the computer can create a 3D image of the surgical area. By converting the entries made by the surgeon on the PC, incisions in the range of a tenth of a millimetre are possible, something that simply cannot be achieved purely by hand. With the help of a computer, the robot is able to check at all times whether the doctor is operating where it is necessary. In case of doubt, the system can stop the doctor and thereby prevent potential medical errors.

Various systems

There is nearly no medical procedure in which a robot-supported operation would not be possible. Already today, more than 70 companies offer systems for a wide range of procedures. For example, procedures on the spinal column, the knee, the hips, in the abdomen, in neurosurgery, in the ear, nose and throat area, during biopsies, in gynaecology and urology or even in operations on the heart or in the eye. The technology is even used in hair transplants. The devices used in the operating room have different designs depending on their purpose. The bandwidth ranges from very voluminous, multi-armed systems to systems that are no larger than a beverage can. While the former is used for complex procedures, the latter system is used simply to accurately hold the instruments at the desired position.

Medical technology with drive

The patient is aware of nothing that happens in the operating room. The anaesthesia works. An anaesthetist closely monitors the vital functions. She can rely on FAULHABER for the artificial ventilation. Operating in the turbine unit of the ventilator that is integrated in the anaesthesia system is a brushless, high-speed DC-motor with a diameter of just 24 mm. Not only is the motor extremely fast and quiet over the entire speed range but also extremely dynamic. This enables very natural ventilation. Adults, children and newborns can all thereby be ventilated adequately and as naturally as possible throughout the entire anaesthesia. In addition, the turbine-based ventilation allows the patients to breathe freely (spontaneous breathing) at all times.

Because robot-supported operations are being performed in an increasing number of disciplines, the need for drive systems is growing as well, such as for the positioning of robot arms. Highly dynamic systems that deliver the full speed in the shortest possible time are needed here. Thanks to their ironless winding technology and flat speed-torque curves, FAULHABER Drive Systems have all the necessary properties, such as exact positioning and speed control. High-performance motor families such as the FAULHABER BX4 or BP4 and the new BXT series, complemented by the extensive range of gearheads, optical, magnetic or absolute encoders as well as Speed and Motion Controllers, are ideally suited for demanding robotics applications not only in medicine but in many other areas as well.

Daily routine

Robot-supported operations are not just a futuristic vision but are daily routine in many operating rooms around the world today. Even though a telemedical operation has already been performed – where the doctor sat at a monitor in the USA and operated on a patient in France – in practice, it generally looks like this: robot and computer serve as assistants to the people on-site in the operating room. Years of medical experience cannot simply be converted into a programming language. But surgeries can be made safer through the use of robots. And FAULHABER will play an important role. Both for as well as in the patient.

Surgical robot (faulhaber.com)

Company box: The drive experts from Schönaich

FAULHABER is specialized in the development, production and deployment of high-precision miniaturized and miniature drive systems, servo components and drive electronics with up to 200 watts of output power. This includes putting into effect customer-specific packaged solutions as well as an extensive range of standard products, such as Brushless Motors, DC-Micromotors, Encoders and Motion Controllers. The FAULHABER trademark is recognised worldwide as a symbol of high quality and reliability in complex and demanding application areas, such as medical technology, factory automation, precision optics, telecommunications, aviation and aerospace, and robotics. From the powerful DC-motor with a continuous torque of 200 mNm to the filigree micro drive with an outer diameter of 1.9 mm, the FAULHABER standard range can be combined in more than 25 million different ways to create the optimum drive system for a particular application. At the same time, this technological construction kit is the basis for modifications which allow to configure special versions to meet the specific needs of customers.

www.faulhaber.com